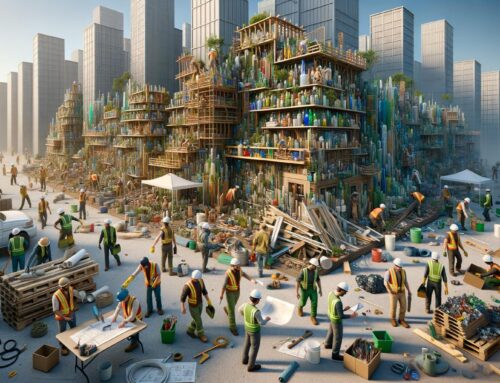

At Home Owners Association, we understand the importance of selecting the right materials for your construction projects. Lightweight building materials have become increasingly popular due to their numerous benefits and versatility.

In this blog post, we’ll explore how to choose the best lightweight materials for your needs, considering factors such as structural requirements, thermal properties, and cost-effectiveness.

What Are Lightweight Building Materials?

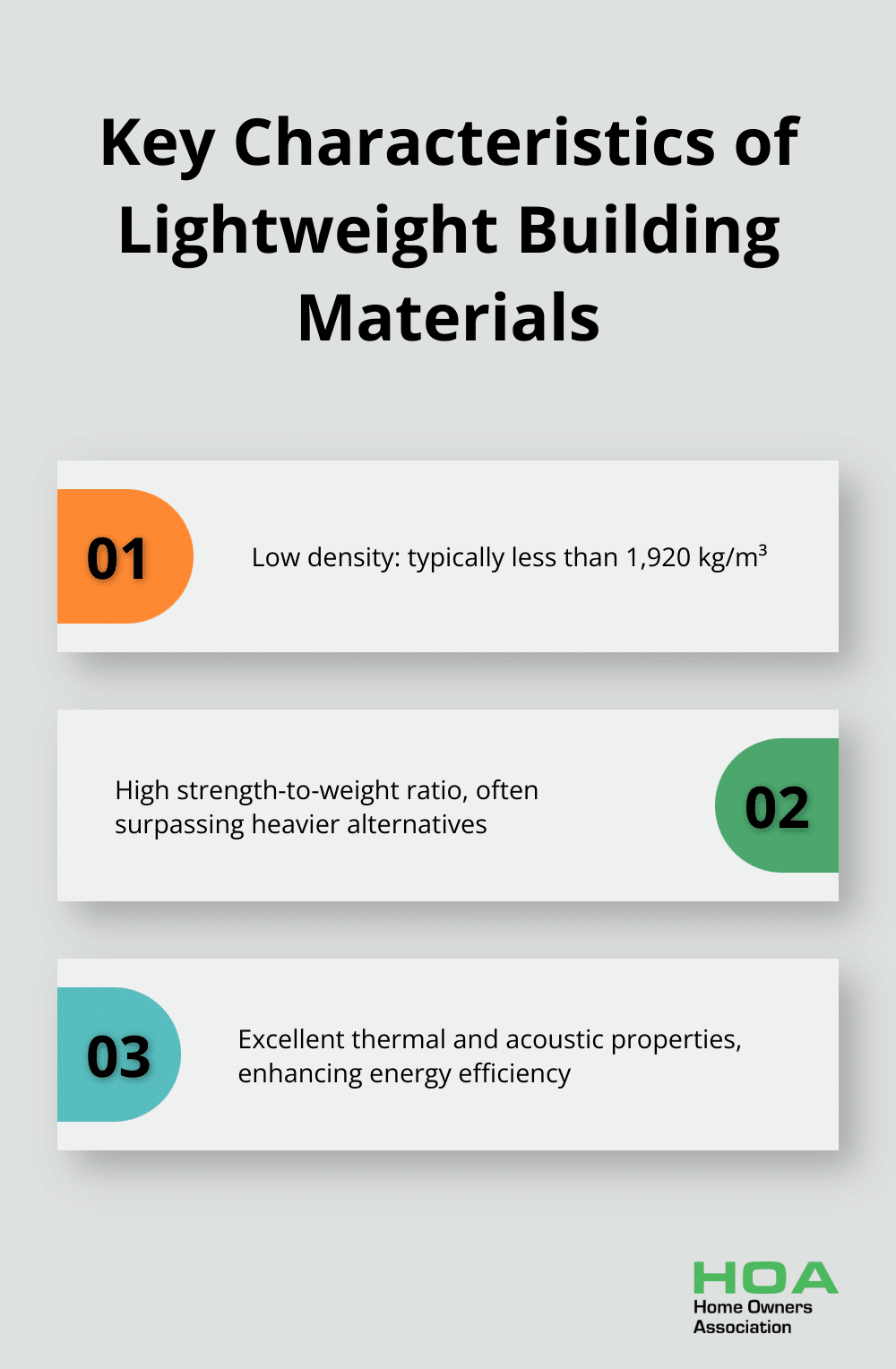

Definition and Key Characteristics

Lightweight building materials are construction components that weigh significantly less than traditional options while still providing structural integrity. These materials typically have a density of less than 1,920 kg/m³, making them easier to handle and transport. They offer excellent strength-to-weight ratios, often surpassing heavier alternatives. High strength and light weight are two recent opposite development trends of concrete. These materials also boast impressive thermal and acoustic properties, enhancing energy efficiency and comfort in buildings.

Benefits of Lightweight Construction

The use of lightweight materials in construction projects yields numerous advantages. It reduces the overall weight of the structure, potentially decreasing foundation costs and allowing for taller buildings. According to the Australian Building Codes Board, lightweight construction can lead to a 20-30% reduction in structural loads.

Transportation and handling costs also decrease significantly. A study by the CSIRO found that using lightweight materials can cut transportation emissions by up to 40% compared to traditional building materials. This not only saves money but also contributes to more sustainable construction practices.

Common Types of Lightweight Building Materials

Several lightweight options have gained popularity in the Australian construction industry:

- Autoclaved Aerated Concrete (AAC) blocks: These blocks are lighter than traditional concrete blocks while providing excellent insulation properties. Transportation also showed differences due to the lower weight of autoclaved blocks, with pressed bricks consuming 1.8 gigajoules of energy.

- Engineered wood products: Cross-laminated timber (CLT) panels can be up to five times lighter than concrete slabs of similar strength, making them ideal for multi-story buildings.

- Expanded Polystyrene (EPS): Used in insulation and as a core material in structural insulated panels (SIPs), EPS can reduce a building’s energy consumption by up to 50% when properly installed.

- Lightweight steel framing: This option is not only lighter than traditional timber framing but also resistant to termites and fire, addressing common concerns in Australian housing.

Industry Trends and Future Outlook

The construction industry continues to evolve, with a growing interest in lightweight materials among builders and homeowners. Many report significant cost savings and improved energy efficiency after incorporating these materials into their projects. As technology advances, we expect to see even more innovative lightweight solutions entering the market, further revolutionizing construction methods in Australia.

Now that we’ve explored the basics of lightweight building materials, let’s examine the factors to consider when choosing these materials for your specific project needs.

What Factors Matter When Selecting Lightweight Materials?

Structural Integrity and Load-Bearing Capacity

The primary consideration in choosing lightweight building materials is their ability to withstand structural loads. Despite reduced mass, these materials must provide adequate strength. Autoclaved aerated concrete (AAC) blocks can be used for loadbearing structures up to 3 storeys, making them suitable for low-rise buildings. For taller structures, lightweight steel framing offers strength comparable to traditional steel at a fraction of the weight.

A structural engineer’s consultation ensures chosen materials meet specific load requirements. The Building Code of Australia (BCA) provides guidelines on structural performance that apply to all materials, regardless of weight.

Thermal and Acoustic Performance

Lightweight materials often excel in thermal insulation, significantly impacting energy efficiency. Foam board, primarily composed of rigid polymer foams like EPS, XPS, or polyiso, offers superior thermal resistance per inch of thickness compared to fiberglass insulation. This superior insulation can lead to energy savings of up to 50% in some cases.

Acoustic properties are equally important, especially in multi-unit dwellings. Engineered wood products can provide excellent sound insulation. Some cross-laminated timber (CLT) panels achieve a Sound Transmission Class (STC) rating of up to 60, considered very good for residential construction.

Fire Resistance and Safety Compliance

Fire safety is paramount in Australian construction. The National Construction Code (NCC) sets strict fire resistance requirements for all building materials. Many modern lightweight options perform exceptionally well in this regard.

Some lightweight steel framing systems achieve a fire resistance level (FRL) of up to 240/240/240, maintaining structural adequacy, integrity, and insulation for up to 4 hours in a fire. Certain AAC products have been tested to achieve an FRL of 240/240/240 when used in wall systems.

Long-Term Cost-Effectiveness and Durability

Initial costs matter, but long-term economic benefits of lightweight materials are essential to consider. Reduced transportation and labor costs, lower foundation requirements, and improved energy efficiency can lead to significant savings over time.

Durability is another key aspect. Some lightweight materials, like fiber cement, can last up to 50 years with proper maintenance. This longevity can offset higher initial costs and reduce the need for frequent replacements or repairs.

When evaluating cost-effectiveness, consider the entire lifecycle of the material. While traditional concrete might seem cheaper initially, lightweight alternatives like AAC can offer savings of up to 30% on overall construction costs (factoring in reduced structural requirements and improved thermal performance).

The construction industry continues to innovate, with new lightweight materials entering the market regularly. These advancements promise even greater benefits in terms of strength, insulation, and cost-effectiveness. As we explore specific lightweight building materials in the next section, you’ll see how these factors come into play in real-world applications.

Top Lightweight Building Materials for Modern Construction

Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS)

EPS and XPS have revolutionized insulation in the construction industry. These foam-based materials offer excellent thermal resistance, with R-values ranging from 3.6 to 5.0 per inch. A 4-inch thick panel can provide insulation equivalent to a 12-inch thick traditional fiberglass batt.

Using EPS or XPS in walls and roofs can reduce heating and cooling costs by up to 40%, according to CSIRO studies. These materials are incredibly lightweight (densities ranging from 16 to 32 kg/m³), which makes them easy to transport and install.

Structural insulated panels (SIPs) are known to be about 50% more energy-efficient than traditional timber framing. This time-saving aspect has increased the popularity of SIPs among self-build projects.

Autoclaved Aerated Concrete (AAC) Blocks

AAC blocks have gained traction due to their excellent thermal properties and ease of use. These blocks weigh about one-fifth of traditional concrete blocks (approximately 550-650 kg/m³). This lightweight nature significantly reduces transportation costs and eases on-site handling.

AAC blocks can be cut and shaped easily with standard woodworking tools, which reduces waste and speeds up construction. Some builders have reported labor cost savings of up to 30% when using AAC blocks compared to traditional brickwork.

Thermally, AAC blocks provide excellent insulation. AAC blocks are two-and-a-half times lighter than concrete or clay and have a higher insulation value than brick, concrete or earth masonry, with moderate thermal mass. This translates to potential energy savings of up to 30% for heating and cooling.

Lightweight Steel Framing

Steel framing has become a popular option, especially in areas prone to termites or bushfires. Modern lightweight steel frames weigh about 60% less than traditional timber frames, which reduces the load on foundations and potentially lowers construction costs.

The precision of steel framing leads to straighter walls and fewer callbacks (some builders report a reduction in post-construction issues by up to 40%). Steel frames are also dimensionally stable, meaning they won’t warp, twist, or shrink over time, which leads to fewer maintenance issues down the line.

Engineered Wood Products

Engineered wood products, such as cross-laminated timber (CLT) and laminated veneer lumber (LVL), offer the warmth and aesthetics of wood with enhanced structural properties. CLT panels can be up to five times lighter than concrete slabs of similar strength.

CLT has been used to construct multi-story buildings up to 18 stories high. The speed of construction with CLT is remarkable (some projects report a 30% reduction in construction time compared to traditional methods).

LVL beams offer superior strength-to-weight ratios compared to solid timber. They can span longer distances without intermediate supports, which provides more design flexibility. LVL has proven particularly useful in renovation projects where structural reinforcement is needed without adding significant weight to the existing structure.

The lightweight nature of these materials not only simplifies construction but also contributes to more sustainable building practices. Reducing the overall weight of structures can minimize the environmental impact of transportation and potentially use less material in foundations and supporting structures.

Final Thoughts

Selecting the right lightweight building materials impacts the immediate build and long-term performance of your structure. These materials offer advantages such as reduced transportation costs, improved energy efficiency, and faster construction times. The construction industry evolves rapidly, with new lightweight options continually emerging for builders and homeowners.

We at Home Owners Association recommend consulting with professionals who can provide expert guidance tailored to your specific needs. Our team in Melbourne, Australia, offers personalized advice and access to trade pricing. This ensures you make informed decisions that align with local building codes and environmental conditions.

Thoughtful selection of lightweight building materials contributes to a more efficient, sustainable, and cost-effective future. The right lightweight materials can help you achieve your goals in new builds or renovation projects. These choices also support a more sustainable construction industry overall.