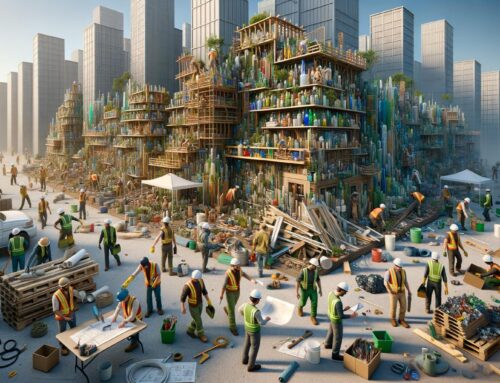

At Home Owners Association, we understand the importance of selecting the right materials for construction projects. Light materials for building have become increasingly popular due to their numerous advantages in modern construction.

These materials offer a perfect balance of strength, durability, and cost-effectiveness while reducing the overall weight of structures. In this blog post, we’ll explore how to choose the best light materials for your construction projects, ensuring optimal performance and sustainability.

Light Construction Materials: Revolutionizing the Building Industry

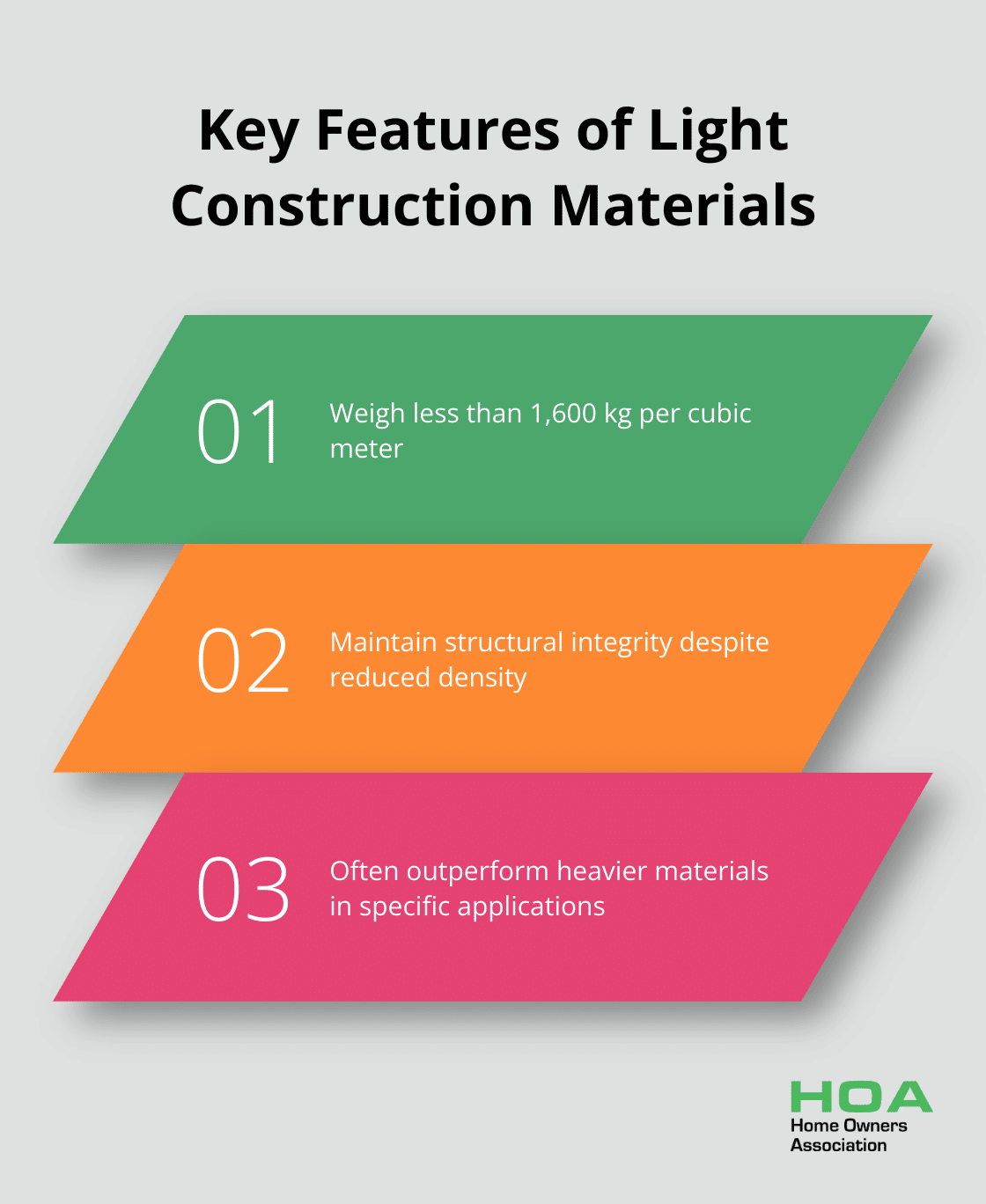

Defining Light Materials in Construction

Light construction materials weigh less than 1,600 kg per cubic meter. This reduced density doesn’t compromise their structural integrity. Many light materials outperform their heavier counterparts in specific applications. Engineers design these materials to maintain strength while significantly decreasing the overall mass of a structure.

The Advantages of Light Materials

Using light materials in construction projects offers numerous benefits. They reduce the dead load on a building’s foundation, which allows for more flexible designs and can lead to cost savings in foundation work.

Transportation costs decrease when using light materials. A truck can carry more units of a lightweight product compared to traditional heavy materials, which cuts down on fuel consumption and emissions. This aligns with the growing demand for sustainable construction practices across Australia.

Light materials make installation easier and faster. Workers experience less fatigue, which leads to increased productivity and potentially shorter project timelines. This can result in significant labor cost savings (a crucial factor in today’s competitive construction market).

Popular Light Materials in Australian Construction

Engineered Wood Products

Cross-laminated timber (CLT) panels are gaining traction in Australia. These strong, lightweight panels can be used for walls, floors, and roofs. They offer numerous advantages, including reduced construction times and exceptional structural performance.

Aluminum and Its Alloys

Aluminum and its alloys offer an excellent strength-to-weight ratio and resist corrosion. This makes them ideal for coastal areas where salt air can quickly degrade other materials.

Aerated Autoclaved Concrete (AAC) Blocks

AAC blocks weigh about one-fifth of traditional concrete. They’re available as panels and blocks, with wall panels typically used for cladding but can also be loadbearing. AAC provides good insulation and fire resistance, and is easy to cut and shape on-site, which reduces waste and speeds up construction.

Fiber-Reinforced Polymers (FRP)

FRP composites are incredibly strong, lightweight, and resist corrosion. Construction teams often use them in bridge construction and for strengthening existing structures.

Bamboo

Bamboo is emerging as a sustainable light material option. It grows fast, offers strength, and has a lower environmental impact compared to many traditional building materials. While its use remains limited in Australia, interest is increasing, especially in eco-friendly building projects.

The construction industry continues to innovate with light materials, pushing the boundaries of what’s possible in building design and efficiency. As we move forward, it’s essential to consider the factors that influence material selection for specific projects. Let’s explore these considerations in the next section.

Factors to Consider When Choosing Light Materials for Construction

Structural Integrity and Load-Bearing Capacity

The selection of light materials for construction projects hinges on their ability to meet structural demands. Cross-Laminated Timber (CLT) panels can support loads comparable to concrete while being five times lighter. Since 2015, CLT has gained popularity due to its impressive strength-to-weight ratio.

Collaboration with a structural engineer is essential to determine specific project requirements and ensure compliance with local building codes. This professional input guarantees that chosen materials will meet or exceed necessary standards.

Durability in Varied Environmental Conditions

Australia’s diverse climate necessitates materials capable of withstanding a range of environmental challenges. Coastal areas require corrosion-resistant materials, while bushfire-prone regions demand fire-resistant options.

Fiber cement cladding excels in coastal environments. It offers homeowners a durable solution for weather resilience, meeting strict wind and moisture resistance requirements in wet coastal areas.

Cost-Effectiveness and Market Availability

Light materials often come with higher upfront costs, but it’s important to consider long-term savings. Reduced transportation and labor costs, faster construction times, and potential energy savings can offset initial expenses.

Availability plays a critical role in material selection. Some innovative materials might have limited suppliers, potentially causing delays or increased costs. It’s advisable to research and secure reliable suppliers before committing to specific materials.

Environmental Impact and Sustainability

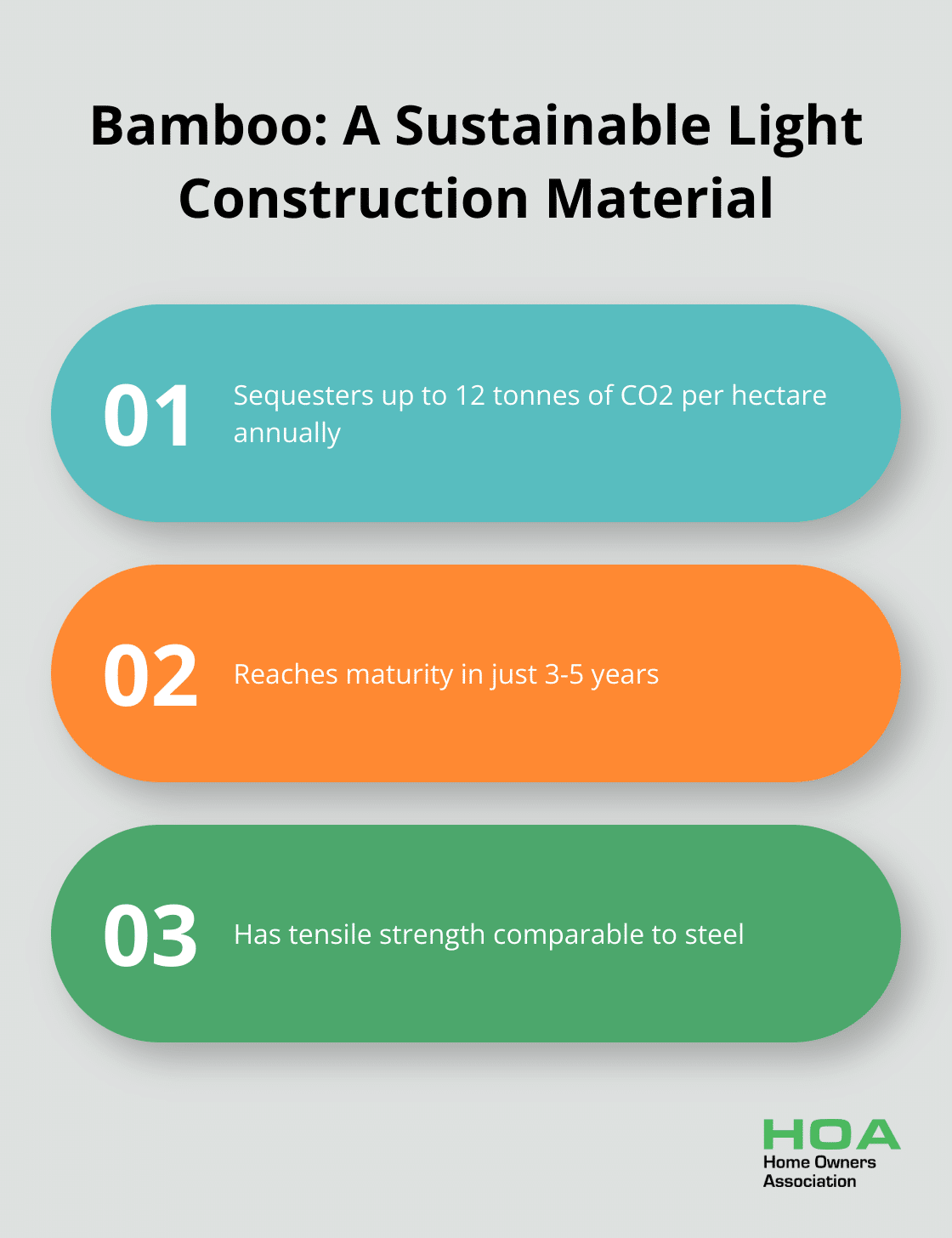

Sustainability has become a non-negotiable aspect of modern construction. Many light materials offer significant environmental benefits. Bamboo, for instance, can be harvested in just 3-5 years and sequesters carbon as it grows.

When evaluating materials, consider their entire lifecycle impact, including production energy, transportation emissions, and end-of-life recyclability. Environmental product declarations (EPDs) provide standardized information about a material’s environmental performance, aiding in informed decision-making.

Balancing Factors for Optimal Selection

The ideal light material for a construction project strikes a balance between structural requirements, environmental resilience, cost-effectiveness, and sustainability. This balance will vary depending on the specific needs and constraints of each project.

As we move forward, it’s valuable to examine how these factors apply to popular light construction materials. The next section will compare various options, helping you make informed decisions for your specific project needs.

Which Light Materials Excel in Construction?

At Home Owners Association, we’ve observed how the right choice of light materials can transform construction projects. Let’s compare some popular options to help you make informed decisions for your next build.

Aluminum: The Versatile Powerhouse

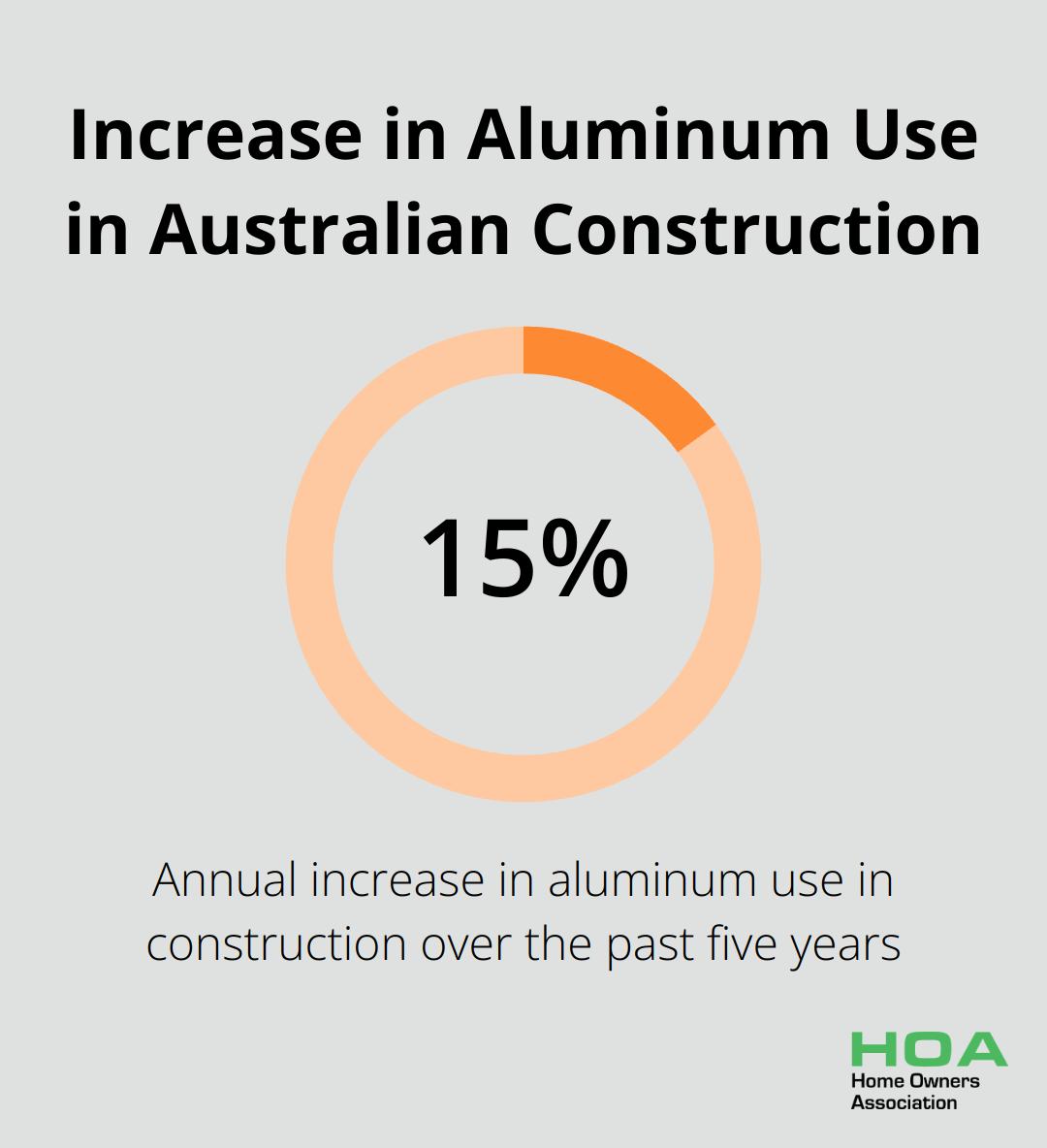

Aluminum and its alloys stand out for their exceptional strength-to-weight ratio. In Australia’s coastal regions, where corrosion resistance matters, aluminum excels. It weighs 2.5 times less than steel yet offers comparable strength in many applications. The Australian Aluminium Council reports that aluminum use in construction has increased by 15% annually over the past five years, highlighting its growing popularity.

Aluminum’s versatility extends to various applications, from structural framing to cladding and roofing. Its ability to be easily extruded into complex shapes makes it ideal for custom architectural designs. However, aluminum has a higher initial cost compared to some traditional materials, which can be offset by its longevity and low maintenance requirements.

Engineered Wood: Strength Meets Sustainability

Engineered wood products, particularly Cross-Laminated Timber (CLT), revolutionize Australian construction. A study supports the economic benefits when comparing CLT to concrete and steel construction. It concludes that building with CLT may offer advantages in terms of cost and efficiency.

The Timber Development Association of Australia states that CLT buildings can be constructed up to 30% faster than traditional concrete structures. This speed (combined with its prefabrication potential) makes CLT an attractive option for time-sensitive projects.

Aerated Concrete: Lightweight Insulation Champion

Aerated Autoclaved Concrete (AAC) blocks have gained traction in Australia for their excellent insulation properties and fire resistance. AAC weighs just 20% of traditional concrete, which significantly reduces structural loads. A CSIRO study investigated new house construction around Australia to gain insight into the quality of house construction with regard to energy efficiency.

AAC’s ease of installation is another major advantage. Workers can easily cut and shape blocks on-site, which reduces waste and speeds up construction. However, AAC requires specialized skills for optimal installation, which may impact labor costs.

Fiber-Reinforced Polymers: High-Tech Performance

Fiber-Reinforced Polymers (FRP) offer unparalleled strength-to-weight ratios. These materials weigh up to 75% less than steel and 30% less than aluminum. In bridge construction, FRP decks have shown a lifespan of over 100 years with minimal maintenance (according to studies by the University of Queensland).

FRP’s corrosion resistance makes it ideal for harsh environments. However, its higher upfront cost can be a barrier for some projects. It’s important to consider the long-term benefits, including reduced maintenance and extended lifespan, when evaluating FRP for your construction needs.

Bamboo: The Sustainable Newcomer

While still emerging in Australian construction, bamboo offers exciting potential as a sustainable light material. It reaches maturity in just 3-5 years and has a tensile strength comparable to steel. The University of Technology Sydney has conducted research showing that bamboo can sequester up to 12 tonnes of carbon dioxide per hectare annually, making it an environmentally attractive option.

Bamboo’s use in construction remains limited in Australia, primarily due to lack of standardization and limited local supply. However, as sustainability becomes increasingly important, we anticipate growing interest in this versatile material.

Final Thoughts

Light materials for building offer numerous advantages in construction projects. They reduce transportation costs, speed up construction times, and improve energy efficiency. However, project managers must evaluate each option’s long-term performance and environmental impact carefully before making decisions.

The construction industry continues to innovate, introducing new light materials and improving existing ones. We at Home Owners Association recommend consulting with experts and suppliers before finalizing material choices. Their specialized knowledge will help navigate the complexities of material selection and ensure compliance with local building codes and regulations.

For homeowners in Melbourne looking to maximize their construction and renovation projects, the Home Owners Association offers exclusive benefits (including access to trade pricing and expert advice). Our personalized guidance can help you make informed decisions about light materials and other aspects of your home improvement journey. The future of construction lies in these innovative materials, and embracing them can lead to remarkable results in your building projects.