At Home Owners Association, we’re fascinated by the engineering marvels that shape our urban skylines. High-rise building construction materials play a pivotal role in creating these towering structures.

From the strength of structural steel to the versatility of concrete and the elegance of glass facades, each material contributes uniquely to the design and functionality of skyscrapers. In this post, we’ll explore the key materials that make modern high-rises possible and their specific applications in tall building construction.

What Makes Steel the Backbone of Skyscrapers?

Structural steel stands as the unsung hero of modern skyscrapers, providing the strength and flexibility needed to reach unprecedented heights. This material has revolutionized high-rise construction across Australia.

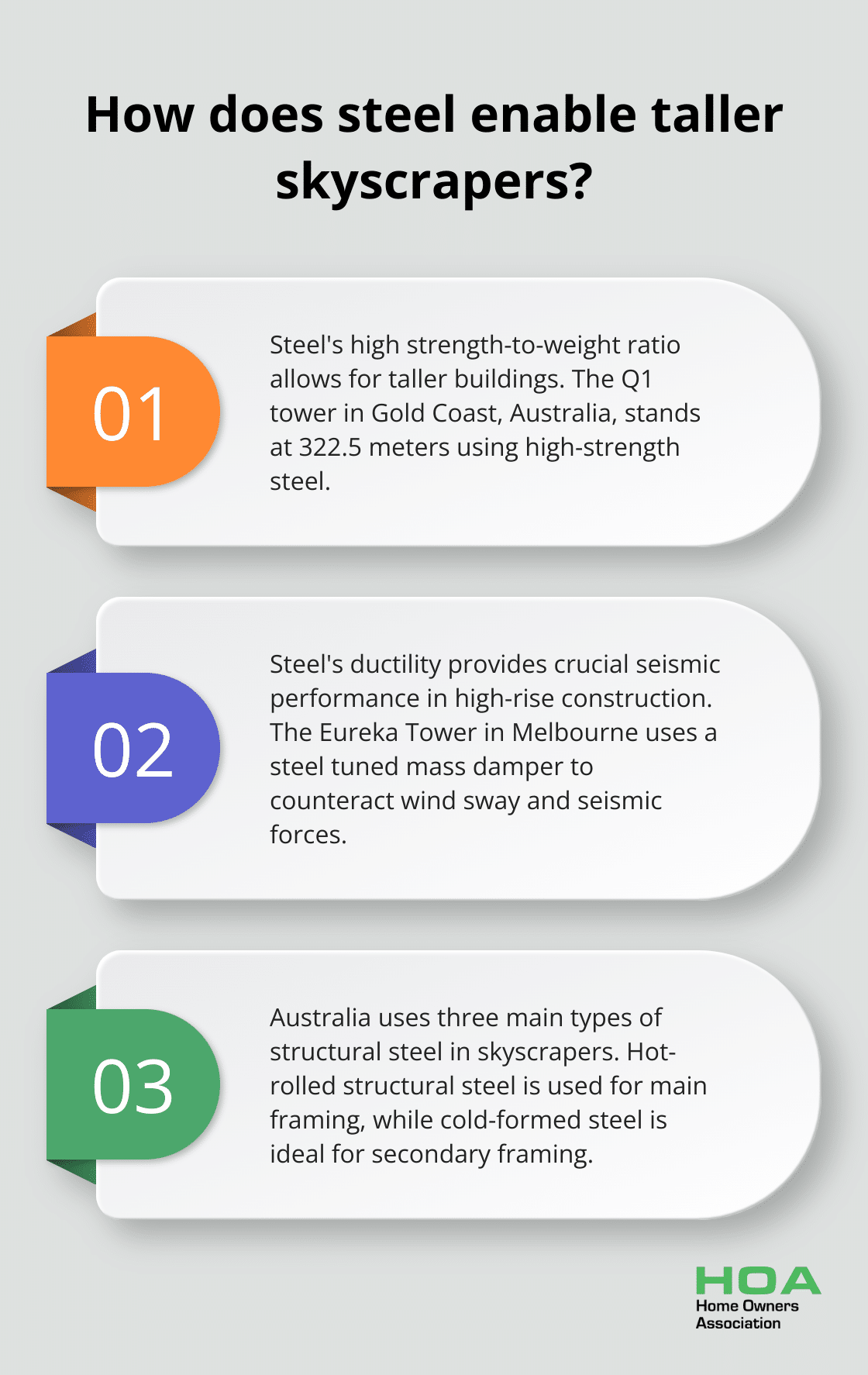

The Strength-to-Weight Ratio Advantage

One of the most compelling properties of structural steel is its exceptional strength-to-weight ratio. This allows architects and engineers to design taller buildings without compromising stability. The Q1 tower in Gold Coast, Australia (standing at 322.5 meters) utilizes high-strength steel to achieve its impressive height while maintaining a relatively light structure.

Ductility and Seismic Performance

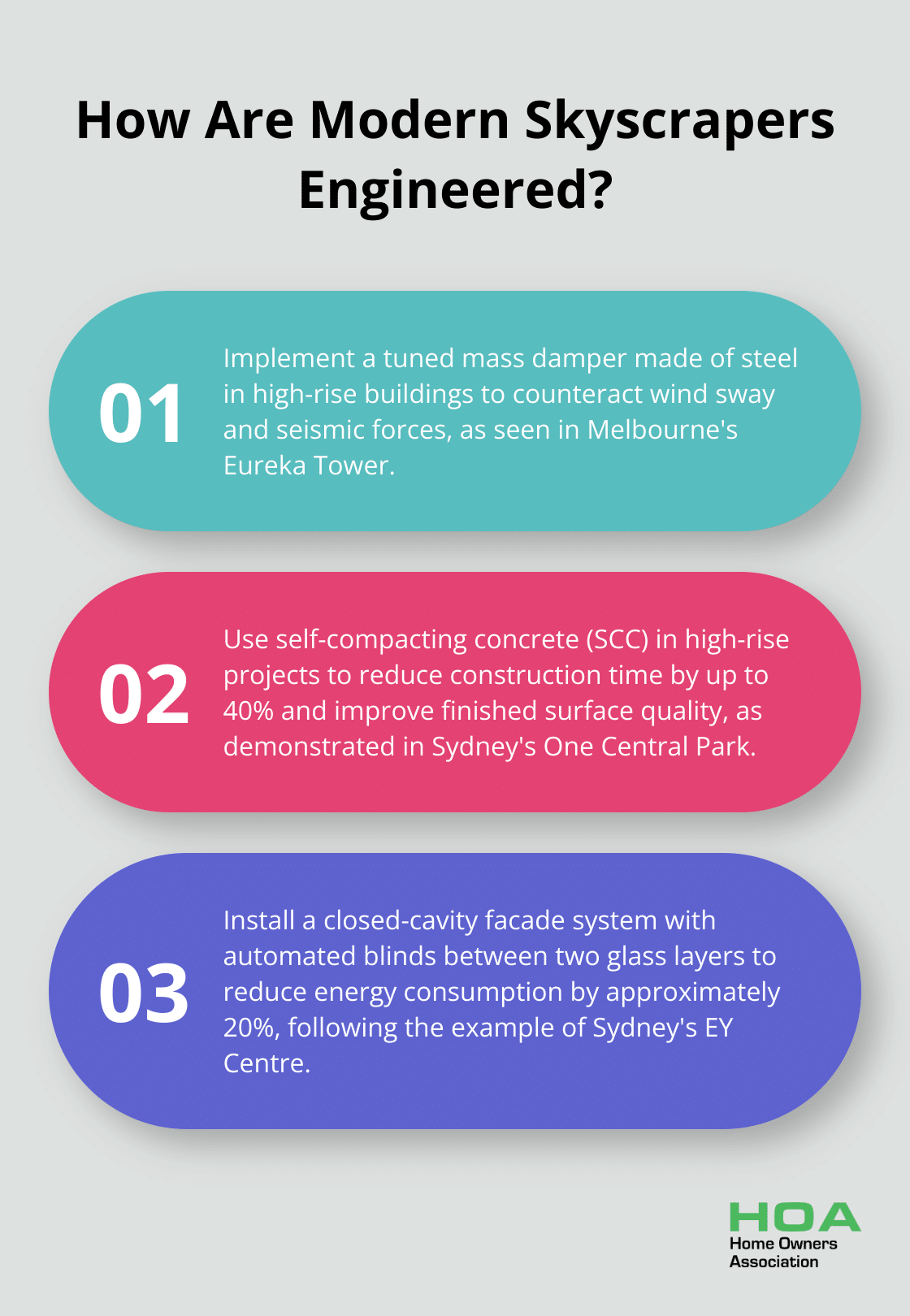

Steel’s ductility proves crucial in high-rise construction, especially in areas prone to seismic activity. This property allows steel structures to bend without breaking, absorbing energy from earthquakes. The Eureka Tower in Melbourne incorporates a tuned mass damper made of steel to counteract wind sway and seismic forces.

Types of Steel in Australian Skyscrapers

Australia commonly uses three types of structural steel in high-rise construction:

- Hot-rolled structural steel: Used for main framing elements due to its high strength and versatility.

- Cold-formed steel: Ideal for secondary framing and non-load bearing walls.

- High-strength low-alloy (HSLA) steel: Employed in specific applications where higher strength and corrosion resistance are required.

The Australian Steel Institute is involved in a five-year project aimed at supporting the transition of Australia’s steel manufacturing industry to a more sustainable, competitive, and resilient future.

Key Applications in High-Rise Buildings

Structural steel finds numerous applications in skyscraper construction:

- Core and outrigger systems: These provide lateral stability to the building. The Barangaroo Tower in Sydney uses this system to achieve its 271-meter height.

- Composite floor systems: Steel beams work in tandem with concrete slabs to create strong, lightweight floors.

- Moment frames: These resist lateral loads and are essential in open-plan office designs popular in modern high-rises.

Construction projects that opt for steel often report faster build times and reduced on-site labor costs.

Innovations in Steel Technology

The future of high-rise construction in Australia looks promising with advancements in steel technology. Fire-resistant steel coatings have improved building safety, while new welding techniques have enhanced joint strength. These innovations allow for even taller and more efficient structures.

As the boundaries of skyscraper design continue to expand, structural steel remains at the forefront, enabling architects and engineers to create iconic buildings that define urban landscapes. Its versatility, strength, and efficiency make it an indispensable material in the world of high-rise construction. Now, let’s explore another essential material that works in tandem with steel to create these architectural marvels: concrete.

How Concrete Shapes Modern Skyscrapers

High-Strength Concrete: The Foundation of Tall Structures

High-strength concrete, with compressive strengths exceeding 60 MPa, has revolutionized skyscraper construction. The Eureka Tower in Melbourne (standing at 297.3 meters) uses concrete with strengths up to 100 MPa in its core and columns. This allows for thinner structural elements, which maximizes usable floor space while maintaining structural integrity.

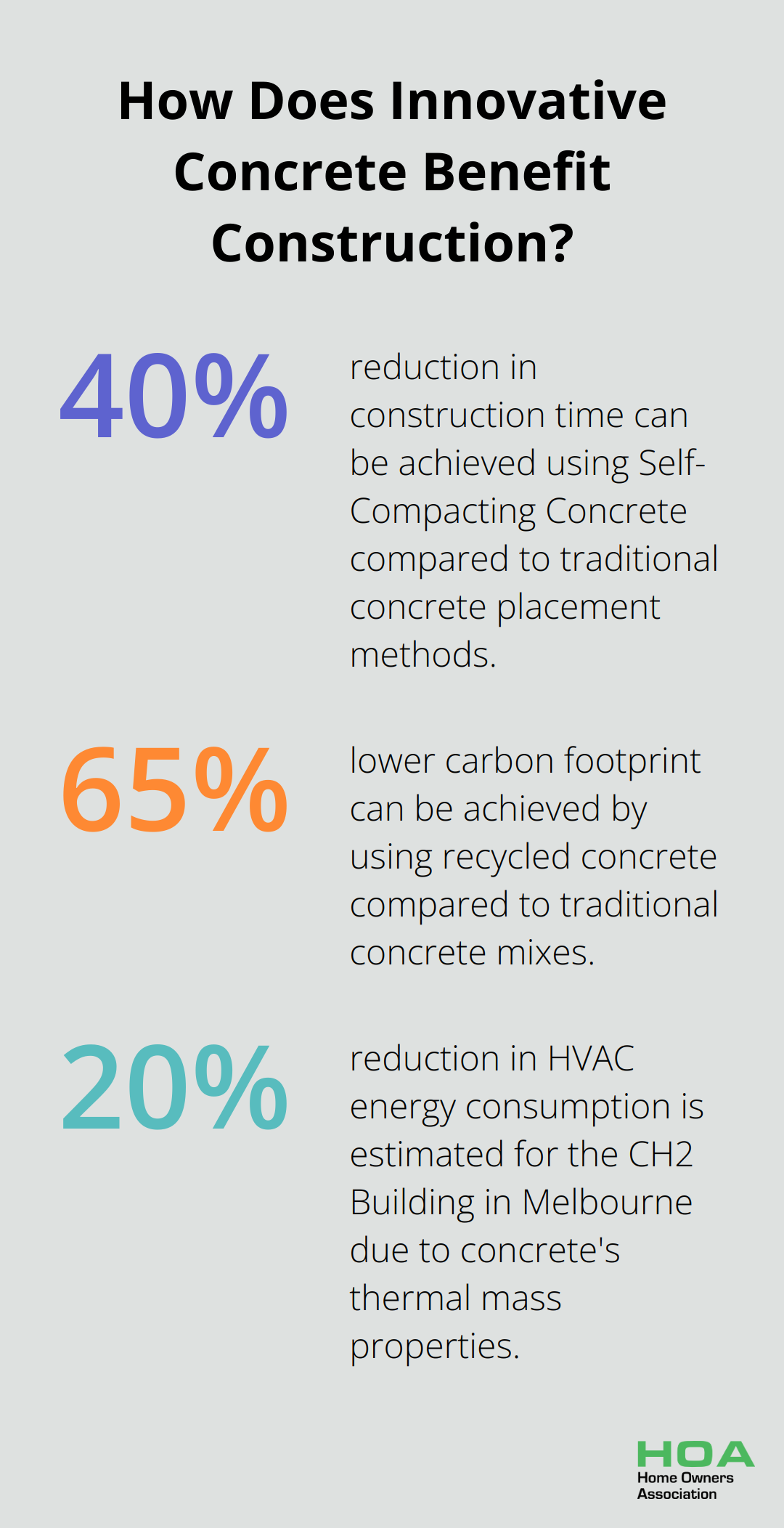

Self-Compacting Concrete: Streamlining Construction

Self-compacting concrete (SCC) has gained popularity in high-rise projects due to its ability to flow into complex formwork without mechanical vibration. The One Central Park in Sydney incorporates SCC in its construction, which reduces labor costs and improves the quality of finished surfaces. The Concrete Institute of Australia reports that SCC can reduce construction time by up to 40% compared to traditional concrete placement methods.

Fiber-Reinforced Concrete: Enhancing Durability

Fiber-reinforced concrete, which incorporates steel, glass, or synthetic fibers, offers improved tensile strength and crack resistance. The Q1 Tower on the Gold Coast uses fiber-reinforced concrete in its core, which enhances its ability to withstand wind loads and reduces the need for traditional reinforcement. The overall design of high-rise buildings is usually dominated by serviceability limit state considerations rather than the ultimate limit state factors.

Innovative Concrete Technologies

Australian engineers have developed a new type of bendable concrete that can withstand earthquakes. This ultra-high performance fiber-reinforced concrete (UHP-FRC) has been tested to be 400 times more bendable than normal concrete, which offers potential for safer and more resilient skyscrapers in seismic zones.

The use of recycled materials in concrete mixes has gained traction in the Australian construction industry. The Barangaroo development in Sydney incorporates recycled concrete aggregates, which reduces the environmental impact of construction. The Green Building Council of Australia reports that using recycled concrete can lower a building’s carbon footprint by up to 65% compared to traditional concrete mixes.

Energy Efficiency Through Thermal Mass

Concrete’s thermal mass properties contribute significantly to energy efficiency in high-rise buildings. The CH2 Building in Melbourne utilizes exposed concrete ceilings to absorb heat during the day and release it at night, which reduces HVAC energy consumption by an estimated 20%.

As architects and engineers continue to push the boundaries of skyscraper design, concrete evolves to meet the demands of modern architecture and sustainability. Its ability to be molded into complex shapes, combined with its strength and durability, ensures that concrete will continue to shape the skylines of Australian cities for generations to come. However, the exterior appearance of these towering structures often relies on different materials. Let’s explore how glass and aluminum create the striking facades that define modern skyscrapers.

How Glass and Aluminum Shape Modern Skyscrapers

The Evolution of Glass in Skyscraper Design

Glass transforms from a simple transparent barrier to an advanced component in modern skyscrapers. Today’s tall buildings use sophisticated glazing systems that enhance performance significantly. The Rialto Towers in Melbourne showcase a double-glazed curtain wall system that reduces solar heat gain/loss while maintaining minimum reflectance compared to single-glazed alternatives.

Low-emissivity (low-E) glass gains popularity in Australian high-rises. This specially coated glass reflects infrared light, which maintains cooler interiors in summer and warmer interiors in winter. The EY Centre in Sydney utilizes a pioneering closed-cavity facade system with automated blinds between two glass layers, which reduces energy consumption by an estimated 20%.

Electrochromic glass, capable of changing its tint electronically, attracts attention. Although relatively new in Australia, this technology has the potential to cut HVAC energy use by up to 20% in commercial buildings (according to a Lawrence Berkeley National Laboratory study).

Aluminum: The Unsung Hero of Curtain Wall Systems

Aluminum’s lightweight yet durable nature makes it ideal for curtain wall systems in high-rise buildings. The material’s strength-to-weight ratio allows for larger glass panels and more intricate designs without compromising structural integrity.

In Australia, anodized aluminum receives favor for its corrosion resistance, especially in coastal areas. The Q1 Tower on the Gold Coast incorporates anodized aluminum in its curtain wall system, which proves resilient against the harsh marine environment.

Thermal break technology in aluminum framing systems revolutionizes energy efficiency in high-rises. The insertion of a less conductive material between the interior and exterior aluminum profiles significantly reduces heat transfer. The Barangaroo Tower in Sydney employs this technology, which contributes to its 5-star NABERS Energy rating.

The Future of Facade Materials

Innovative materials push the boundaries of skyscraper design. Photovoltaic glass, which generates electricity while maintaining transparency, receives exploration for high-rise applications. While not yet widely adopted in Australia, this technology could potentially offset a building’s energy consumption by up to 50%.

The integration of smart technologies into facade systems promises to further enhance building performance. From self-cleaning glass to dynamic shading systems, these innovations will continue to shape the skylines of Australian cities, creating more efficient and sustainable urban environments.

Sustainable Practices in Facade Construction

Recycled aluminum, which requires only 5% of the energy needed for primary production, gains popularity in curtain wall systems. This trend aligns with the growing interest in sustainable facade materials among property owners and developers.

The use of these eco-friendly materials not only reduces the environmental impact of construction but also contributes to the overall energy efficiency of high-rise buildings. As sustainability becomes a key focus in urban development, we expect to see more innovative and environmentally conscious facade solutions in future skyscraper projects.

Final Thoughts

High-rise building construction materials shape our urban landscapes. Structural steel provides strength and flexibility, while concrete offers versatility and durability. Glass and aluminum create striking facades that define the aesthetic appeal of these architectural marvels.

The future of skyscraper construction promises exciting developments. Advanced composites may offer greater strength-to-weight ratios than steel. Smart materials could revolutionize energy efficiency, while self-healing concrete might enhance longevity and sustainability.

At Home Owners Association, we understand the complexities of construction projects. Our members in Melbourne benefit from trade pricing and discounts on high-quality materials (including those used in high-rise construction). We provide expert advice to ensure projects meet the highest standards, whether for high-rise developments or home improvements.